BLDC is a new term emerging in the fan market. BLDC simply the short form of brushless direct current. This motor technology is adopted to ceiling/pedestal fans. Here we will discuss the differences between BLDC fan and normal fan.

Normal fan

Normal fan uses induction motor. It has the following parts

- Stator – Non-rotating part of the motor

- Rotor – Rotating part of the motor

The stator contains coil winding, when AC(alternating current) pass-through this coil it generates a fluctuating magnetic field. This field will interact with the rotor and it causes the rotor to rotate.

Speed of the fan can be controlled using the regulator. Resistance is used in the regulator to control speed. These regulators are inefficient because lots of heat generated due to power loss. It is a brushed motor with mechanical contact so wear and tear will happen in the long term use.

BLDC fan

BLDC fan uses brushless DC(direct current) motor. It converts alternating current to direct current using electronic circuits. It has the following parts

- Stator

- Rotor

- Electronic circuits

One of the main difference between BLDC fan and normal fan is difference in motor commutation method. Commutation simply means a technique used to change the direction of current flow in motor. BLDC motor does not contain any mechanical contact so there is no wear and tear in long-term use.

Speed is controlled using PWM(Pulse Width Modulation) signals. To change the speed of the fan it changes duty cycle of the PWM signals. By changing the width of the PWM signal we can control the fan speed. So there is no resistive heat energy loss in BLDC fan.

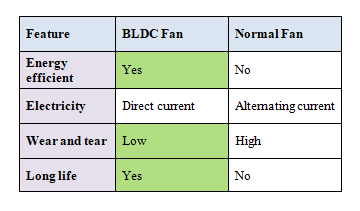

We can summarize difference between BLDC fan and normal fan as shown below

From this, we can conclude that BLDC fans are energy-efficient and long life. Are you started using BLDC fans at your home?

Hope you enjoyed this article, if you like it please don’t forget to share it with your friends.